Products

WKse series single-suction double screw pump

Features

- Fast cleaning and convenient

- Delivery medium smoothly without any disturbing and pulsation

- With high self priming ability and can deliver the liquid mixed with gas or air

- No metallic contact between rotating parts,the medium can contain a bit of solid grain(such as kaolin)

- Can dry running in a short time(≤2min)

- The viscosity of medium can reach up to 100000mm2/s

- Adjust capacity by changing speed,export pressure keeps steady

- Use synchronous gear, external bearing

- All kinds of driving style are suitable

- Can select different joint style (such as flange or arc screw)

- Easy to dismantle and maintain

- High efficiency and economize on energy

Scope of performance

- Pressure range: 1.2MPa

- Flow range: 40m3/h

- Temperature range: less than or equal to 120 DEG C

- Medium viscosity: less than 1 * 105mm2/s

- Speed range: 2000rpm

- suction height: WC = 9m

Construction

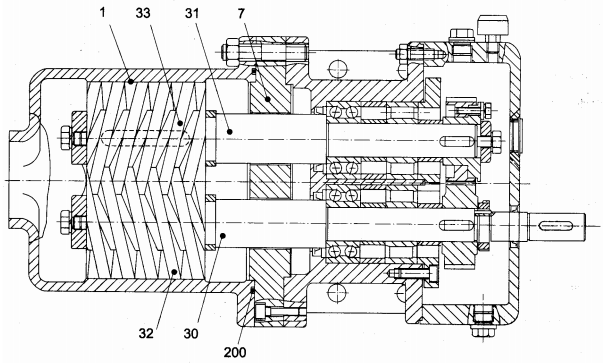

OPERATING PRINCIPLE AND STRUCTURE FEATURE:

During the operating, sealed cavities are formed between the screws, screw and stator inner. The medium inputs the pump casing from inlet, then enters into the sealed cavities, it is delivered to the outlet smoothly along with the rotating of the screw. The stator inner is relatively positioned by stopping port, the spindles are positioned by bearing support. There is no contact between screws, screw and stator inner during the operating. Then there is no dangerous even dry running in a short time. The pump is allowed to deliver various mediums ( such as non-Newton liquid, lubricating and non-lubricating liquid, corrosive liquid etc).

Due to the special design of the inlet conduit and the lower axial speed, the pump has a high suction performance i.e. a low NPSHr.

It is optional either mechanical sealing structure or rubber oil sealing structure. Bearings endure axial force with a long life.

The bearings and synchronous gears are lubricated by the oil in the gear case; the discharging bore is designed on the top of the pump, there are still enough mediums in the pump casing when the pump stops, thus the pump has a high self priming ability.

It’s easy to dismantle the joint screws and wash the pump casing, screw and mechanical sealing directly. All parts coming into contact with the pumped liquid can be cleaned. Please use stream under 180℃ or other medium to wash or disinfect the pump.

It’s possible to mantle safety equipment on the outlet.(such as overfall valve, pressure-controlled valve, relief valve etc).

The pump unit can be designed as a moveable style (baseplate has four wheels and towing handrail).

STRUCTURE INSTRUCTION:

- Maximum pressure :1.6MPa

- Joint way for inlet and outlet:

① Flange joint

② Pipe thread joint

③ Fast joint

④ Discharging bore on the pump casing:It’s impossible for the pump to be contaminated by the survival.

Application

- Chemical industry: transfer for various acid, alkali, salt solution, resin, glycerin, paraffin, heavy oil, gas and other chemical material.

- Paint industry: printing ink, various paint, color and coating.

- Food industry: alcohol, wine, honey, sugar juice, toothpaste, milk, cream, soy sauce, vegetable oil, animal oil, chocolate and eight-treasure rice pudding.

- Pharmacy: various preparation, glucose serosity and injection liquor.

2016/03/18

2016/03/18- 上一篇:W / V series double suction double screw pump

- 下一篇:没有了